From the composite insulator model upgrading iteration to see China's manufacturing power of the booming development process

Introduction: The Backbone of the Nation on Insulators

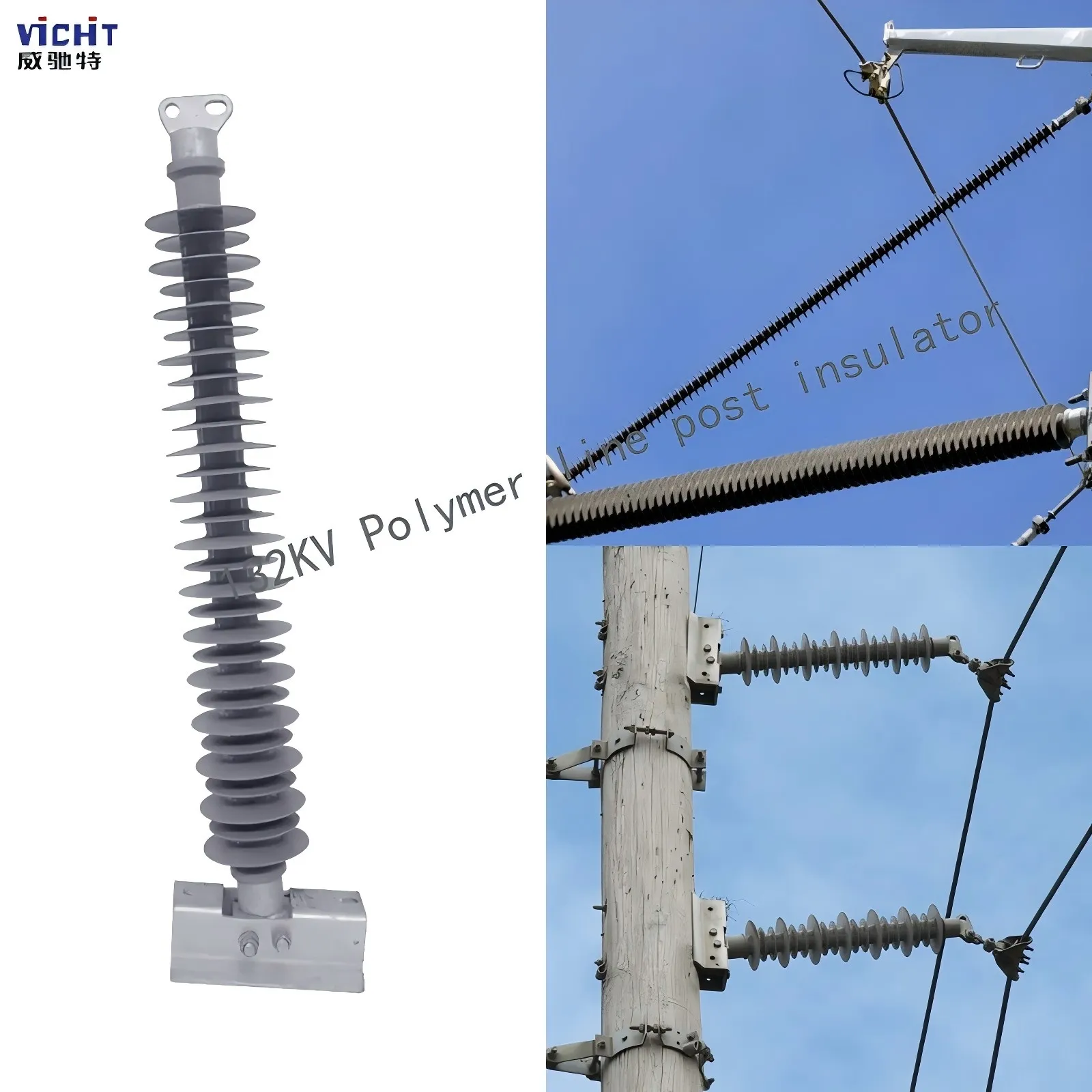

In 1983, China's first batch of domestic composite insulators were quietly put into use in the railroad tunnels of Shih-Tai Line and Bao-Cheng Line. At that time, the umbrella skirt material was cast by hand from high temperature vulcanized silicone rubber, and the connection between the fittings and the epoxy glass fiber reinforced plastic (FRP) mandrels was still a controversy between Tsinghua University's “inner wedge” and Wuhan Institute of Water Conservancy and Electric Power's “outer wedge” technology routes. In the same period, the U.S. Mar-Bal insulators have been monopolizing the global market for nearly a century with “2-8 times the mechanical strength”. Who would have thought that this inconspicuous polymer line insulators, but linked up China's manufacturing industry from penniless to the world's grand epic.

Chinese polymer insulators you do not know the historical truth.

Icebreaker: technology constraints of the “75th Five-Year Plan”

In the 1980s, China's power system was mired in a dirt flash dilemma. Traditional porcelain insulators in the haze ice and snow in the frequent flashover, resulting in iron cap cracking, wire landing, North China power grid was paralyzed for several days due to an accident. And Europe and the United States has long been popularized composite insulators: the United States Glastic company with 68 years of technical deposits, its product life of more than 40 years; Germany Tyco, ABB is holding the 500 kV above the high-end market.

Under the crisis, the national “Seventh Five-Year Plan” listed composite insulators as a research project. Tsinghua University and Wuhan Institute of Water Conservancy and Electric Power laboratory, the birth of the first domestic models:

structure breakthrough: Tsinghua's internal wedge type VS Wushui's external wedge type, the two technical routes in the controversy in parallel;

material dilemmas: silicone rubber formulations rely on imports, the cost of porcelain insulators is three times, the aging problem is unresolved.

The power sector is skeptical of the domestic model, only allowed to test in the following 110 kV “non-important lines” on the grid - this is just like the epitome of Chinese manufacturing at the time: cheap but unreliable, innovative but difficult to gain trust.

Second, the turn: dirt flash accident in the “Jedi counterattack”

In the winter of 1990, North China's large dirt flash accident has become a historical inflection point. When the porcelain insulator in the snow in pieces of failure, test hanging composite insulators were not damaged! Its water-repellent surface to repel dirt, maintenance-free characteristics of the power sector to marvel. Overnight, “China's defense against dirt flash new technology” from the cold subject jumped up for the power grid savior.

Behind this comeback is the ten years of tenacity:

process iteration: acid-resistant mandrels to overcome the problem of brittle breakage, crimping structure instead of easy to loosen the external wedge;

standard self-supporting: In 2002, DL/T 810 was promulgated, and China's first DC composite insulator industry standard was born in the wave of Three Gorges Power Transmission and Transformer Project.

Domestic models have been among the 500kV trunk lines since then. When the imported insulators are still “emphasizing on operation experience”, Chinese engineers have proved in 15 years that the quality of domestic insulators is comparable to those in Europe and the United States, and the price is only half of it.

Third, the top: ultra-high voltage project “big country”

2006, the world's first ± 800 kV composite pillar insulator in Nantong Smarter Power Technology Co. This “big country heavy weapon” completely ended the western technology hegemony for a hundred years:

Performance crushing: explosion-proof, seismic far more than porcelain insulators, the weight is reduced by 70%, so that the extra-high voltage towers to get rid of the burden of the “ultra-long insulator strings;”

Patent barriers: SmarTech to the PCT Patent barriers: Smarter blocked the core technology with PCT patent, forcing Siemens and ABB to give up self-production and turn to purchase Chinese products.

At the same time, China's insulator industry has completed a three-stage jump:

From “copying and following” to “defining the future”:

1983: Shitai Line trial relied on handmade;

2004: hollow composite insulators surpassed international giants;

2025: polymer formula Life expectancy exceeded 50 years, exported to Europe and the United States high-end power grids.

Fourth, against: insulators strung the road to manufacturing power

The evolutionary history of insulators is precisely the miniature epic of China's manufacturing industry:

Stage

| Composite insulator

| Made in China

|

Beginning 1980 | Umbrella skirt rely on imported silicone rubber, hanging network need to be “cautious pilot”

| Shirts for planes. 800 million shirts for one Airbus.

|

Against all odds 1990

| Reliability Proven in Fouled Flash Incidents, Costs Reduced by 50 Percent

| Home Appliances, Textiles Sweep the Globe with Cost-Effectiveness

|

Leading the 2000s

| Extra-high-voltage insulators set ISO standards, anti-sales to Europe and the United States

| High-speed rail, new energy, 5G technology exported to the world

|

China Today:

Robot production of 369,300 units (first half of 2025), 45% localization rate of core components, patents accounted for 2/3 of the world;

New energy vehicles exported 1,060,000 units in six months, BYD's European R&D center landed in Hungary;

Insulators are just a microcosm - from polymer formulations to all-solid-state batteries, from the From “technology recipient” to “rule maker”, China's manufacturing has been reborn in the quenching.

Conclusion: Above the iron tower, the starry river is always bright

When the insulators of Smarter insulators support the extra-high-voltage line in Brazil's Mt. Beauty, and when the Tsinghua Vulcan robot soccer team won the championship in Brazil's RoboCup, the story of Made-in-China has long transcended the “cheap substitution”, and has sublimated into the contribution to the industrial civilization of mankind.

Insulators stand in silence, but string up the mountains and rivers for miles; Made in China wickerwork, finally become the world's star.

This has been questioned “polymer line insulators”, now in the ultra-high voltage towers glittering - it shows the way: from the seventh five attack on the drawings to the world laboratory of the patent wall; and more light up the future: there is a 1.12 trillion robotics market, 900 billion service industry, there is China's smart manufacturing for human beings to carve the next coordinates.

So when foreign friends ask me: how are your insulator products made in China, I hope you can seriously read this article, I think you will understand, you will know how China's insulator manufacturing road is so magnificent, arduous and great, at this moment I think of this year's China's very hot movie (Nezha) in the line, “people in the heart of the preconceived notions of a mountain,” I hope that friends from all over the world can come to China to experience the Chinese environment and feel the Chinese products, I believe you will let go of prejudice, love China's power equipment, love China's polymer composite insulator materials, I believe you will let go of prejudice. "I hope that friends from all over the world can come to China, experience the Chinese environment, feel the Chinese products, I believe that you will let go of preconceived notions, fall in love with Chinese manufacturing, fall in love with Chinese power equipment, fall in love with Chinese polymer composite insulator materials.