At the heart of the African continent, the Democratic Republic of the Congo (DRC) is striving to build stronger and more reliable power infrastructure to support its economic growth and social development. Extreme conditions such as high temperatures, high humidity, heavy rainfall, and complex natural environments impose extremely stringent requirements on critical components of transmission and distribution lines—particularly high-voltage glass insulators and their power hardware—tension clamps.

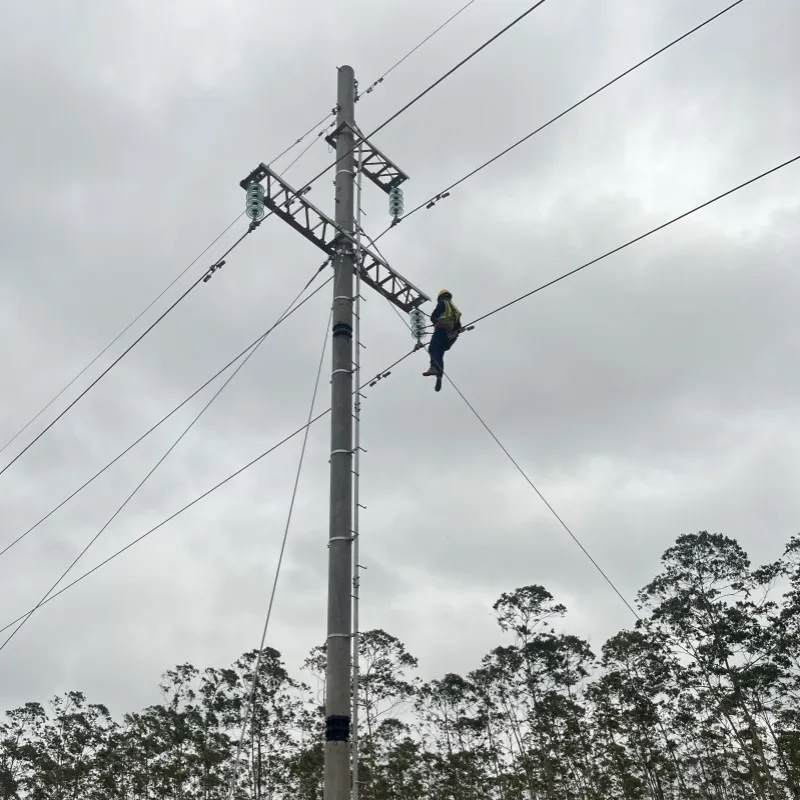

Recently, an electricity company located in an important mining area in the southeastern part of the DRC shared with us the actual application feedback of the high-voltage glass insulators and theirmatching electrical fittings—tension clamps—provided by our Shandong Weichite Power Technology Co., Ltd. on its newly constructed 35kV transmission line. This real-world experience from the front lines of Africa's power sector holds valuable reference value for global customers seeking reliable, cost-effective solutions, especially those facing similar environmental challenges.

Challenges: The Harsh Environment of the Congolese Power Grid

The power company's transmission lines traverse the edges of tropical rainforests and mining areas, characterized by distinct environmental features:

Extreme humidity and precipitation: Annual rainfall is massive, with humidity remaining above 80% during the rainy season, making it highly prone to pollution flashovers.

High salinity and industrial pollution: Mining operations and specific geographical locations result in air containing certain levels of salt and industrial dust.

Temperature fluctuations: Large diurnal temperature variations pose a challenge to the physical stability of materials.

Maintenance difficulties: Some line sections have complex terrain, resulting in high costs and lengthy cycles for manual inspections and maintenance.

Therefore, their core requirements for insulators and power hardware are: exceptional weather resistance, extremely high mechanical strength, excellent anti-pollution flashover performance, and long-term reliability with minimal maintenance.

Solution: High voltage glass insulators made in China and supporting power fittings-tension clamps

Facing these challenges, the power company ultimately chose to collaborate with China's leading high-voltage glass insulator manufacturer, Shandong Weichite. The selected products include:

1. Standard-type high-voltage glass insulators (Cap and Pin Type-U7OB/17O): Used for line suspension strings and some tension strings.

2. Anti-fog Type High-Voltage Glass Insulators: Specifically deployed on sections near mining areas with relatively severe pollution.

3. Matching Hardware - Strain Clamps (Strain Clamp / Dead-End Clamp): Used at line terminals, corners, or large span intervals to bear the full tension of the conductors. Key requirements include good compatibility with insulator strings, strong gripping force, and corrosion resistance.

The project has been in operation for over 18 months, having undergone a complete rainy season and dry season cycle. Maintenance engineers from the power company provided the following positive feedback:

1. “Zero self-explosion” performance: "This is the most impressive aspect for us. In such a humid and temperature-changing environment, some types of insulators we previously used occasionally experienced self-explosion issues. To date, no cases of self-explosion have been reported for this batch of Chinese-made high-voltage glass insulators along the entire line. This has significantly reduced our work in troubleshooting unexpected failures.

2. Excellent anti-pollution flashover capability: “The risk of pollution flashover during the rainy season is our greatest concern. Thanks to the excellent hydrophobicity and self-cleaning properties of the glass surface, as well as the design of the anti-fog insulators, the line's insulation performance recovers very quickly even after prolonged rainfall. Since commissioning, no tripping incidents caused by insulator pollution flashover have occurred on this line.”

3. Reliable anchoring of tension clamps: “TheSupporting power fittings-tension clamps are easy to install, and their grip strength tests fully meet or even exceed standard requirements. After experiencing seasonal temperature changes and fluctuations in conductor tension, all tension points remain stable with no signs of slippage or loosening. Their corrosion protection treatment (such as hot-dip galvanizing) has shown good effectiveness during the current observation period, with no noticeable rusting.”

4. Significantly reduced maintenance costs: “The greatest advantage of glass insulators is their ease of visual inspection. Our line inspectors can clearly determine the condition of the insulators (whether there are any self-explosion defects) using binoculars, eliminating the need for frequent tower climbs for detailed inspections or the use of specialized equipment to measure zero values. This saves a significant amount of manpower and time costs, especially in the vast areas we cover.”

5. High expectations for long-term durability: “Although it is still too early to verify a lifespan of several decades, based on current performance—no spontaneous breakage, no signs of deterioration, and good hardware condition—we are confident that the insulators and hardware provided by Weichai Power Technology Co., Ltd. will operate stably over the long term, meeting or even exceeding our design lifespan expectations.”

Why choose a Chinese glass insulator manufacturer?

The procurement manager of the power company mentioned in feedback: "During the project bidding phase, we evaluated products from multiple sources. The key factors in ultimately selecting this Chinese high-voltage glass insulator manufacturer (Weichit Power Technology Co., Ltd.) were:

Strict compliance with international standards (IEC, ANSI): Complete product certifications and transparent, reliable test reports.

Extensive export experience: The manufacturer has a deep understanding of applications in various climatic conditions across Africa and globally, and can provide targeted recommendations (e.g., recommending anti-fog types).

Strong production capacity and consistency: Ensuring timely delivery and quality stability for large-scale supply.

Highly competitive cost-effectiveness: Providing the optimal overall project cost solution while meeting stringent performance requirements.

Comprehensive supporting capabilities: Able to provide a one-stop solution for hardware tension clamps and other line hardware perfectly matched with insulators, reducing interface risks and procurement complexity."

The case of the Democratic Republic of the Congo Electricity Company strongly demonstrates that Chinese-made high-voltage glass insulators and electrical fittings are fully capable of withstanding the world's most challenging environmental conditions. Their core advantages lie in:

Inherent strength: The zero-value self-explosion characteristic of glass material serves as a “fuse” for safe operation.

Environmental resilience: Exceptional weather resistance and anti-pollution flashover performance, particularly suited for tropical, subtropical, coastal, and industrially polluted regions.

Cost-effective: Long lifespan and low-maintenance or maintenance-free characteristics significantly reduce total cost of ownership (TCO).

Trusted Chinese manufacturing: Leading Chinese manufacturers, backed by advanced technology, scale, and quality control, have become a reliable backbone for global power grid operations.